Our design to serve of your passion

Our design to serve of your passion

Preparation, design, manufacturing, the DNA of Motographe®

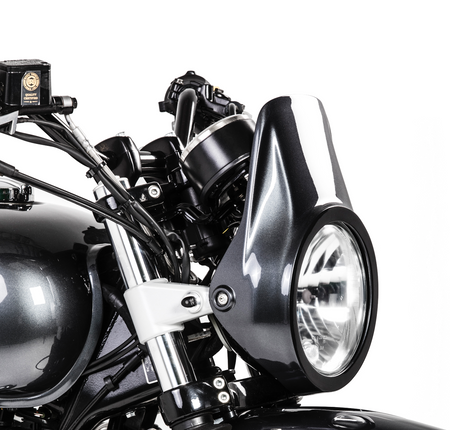

01. Preparation

Since its beginnings, Motographe® has built a solid reputation in the preparation of unique motorcycles. These experiences have shaped our know-how and our deep understanding of the machines and their riders.

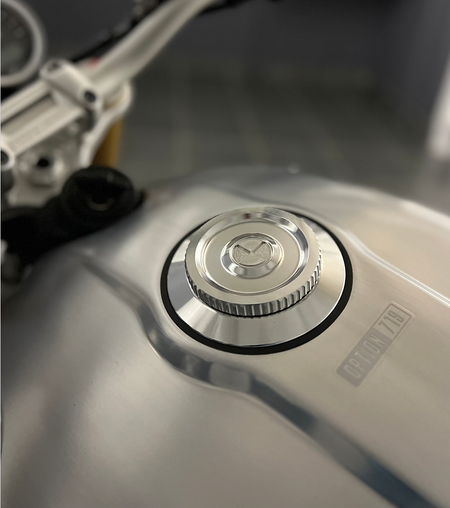

Today, Motographe continues to put its design expertise at the service of all those who wish to enhance their motorcycle. Our parts, recognized for their precision and reliability, are acclaimed by many professionals: specialized garages and renowned preparers trust us for modifications combining performance and aesthetics.

Thanks to our tailor-made solutions, every biker, amateur or professional, can transform their motorcycle with parts worthy of the most prestigious workshops.

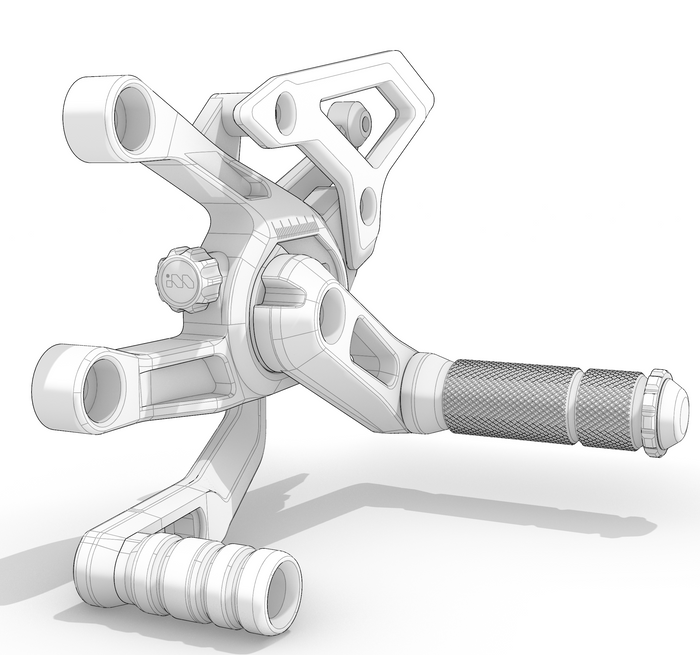

02. Design

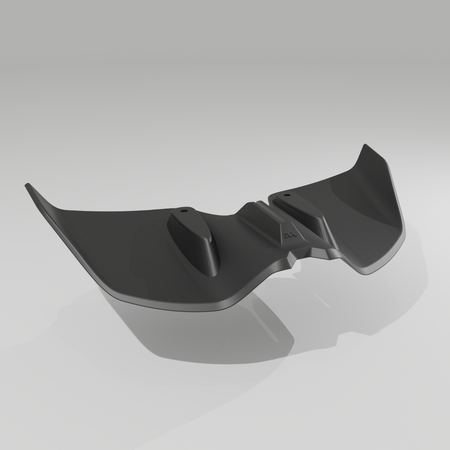

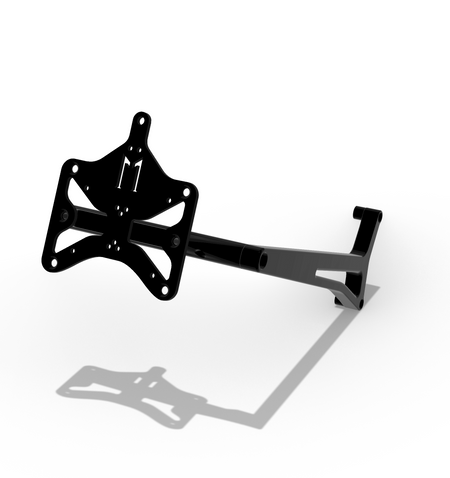

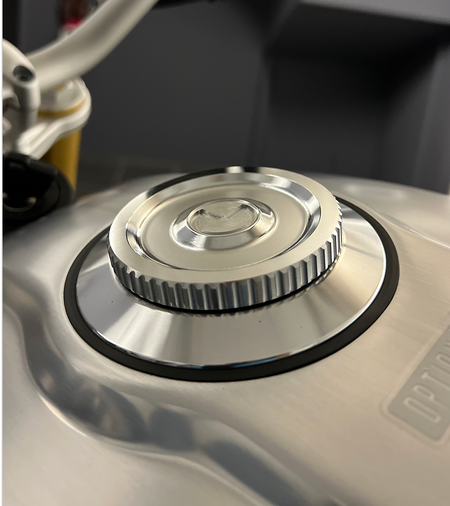

The brand's industrial design expertise is based on a combination of computer-aided design and a rigorous research and development approach. Each product is designed with a clear objective: to combine functionality and neat aesthetics.

Quality materials and unique finishes are carefully selected to bring the best to each motorcycle. The design, although worked in its smallest details, remains at the service of performance and use.

With Motographe®, each component reflects a quest for continuous improvement and a desire to offer ever more accomplished parts.

03. Manufacturing

At Motographe, each product is the result of a rigorous selection of materials as well as manufacturing and finishing processes to guarantee quality and durability. We are using different process such as precision machining for parts requiring adjusted tolerances, molding for complex shapes, and sheet metal for robust and lightweight structures.

The choice of materials, including the different aluminum alloys, is carefully studied according to the mechanical stress that the component will or will not undergo. Each part benefits from adapted finishes, such as specific surface treatments — anodizing, microblasting or polishing — to reinforce resistance to wear and weather while ensuring impeccable aesthetics and operation.

This approach allows us to offer high-performance, durable components that meet the expectations of enthusiasts and professionals alike.